Supply Chain Management

For over 40 years dataCon has been assisting customers in the execution of a supply chain strategy. Early supplier involvement with our customers fosters cross corporate, NPI and material review teams. Material teams can address end of life issues for parts, identify parts not recommended for new designs, and provide timely identification of parts which are on allocation or have long lead times. Our collaborative team approach to NPI addresses a product’s complete including after-market services.

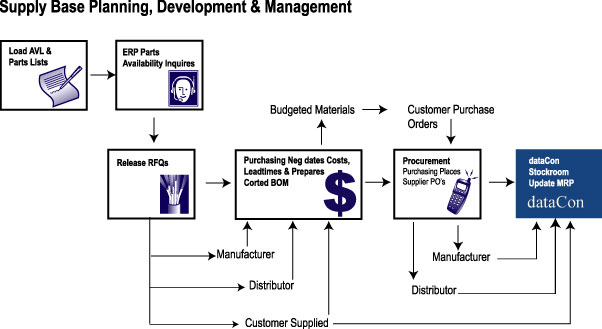

The diagram below shows a typical “quote to build” procurement cycle executed on a daily basis for multiple customers. We have the right personnel at the right time to support your supply chain needs.

Allocation of Operations

dataCon reserves on a quarterly basis a fixed percentage of total shop floor capacity to ensure customers’ forecasts for pilot or recurring builds are delivered on time, just in time, or slightly ahead of schedule. Shop floor release schedules are monitored for work in process (WIP) movement and tracking. Depending upon forecasted customer needs and requirements, dataCon will adjust shift loads or add resources to meet customer delivery and quality expectations.

Materials Planning

The quick turn methodology developed for prototype assembly work is frequently leveraged in follow-on, periodic releases to avoid schedule compression and delays. Previously negotiated risk buy agreements also allow for advanced procurement of long lead time materials. Also, previously negotiated risk buy material agreements help minimize the probability of “line down” or work flow disruptions caused by material shortages.

Line Balancing

Monthly shop floor scheduling is optimized and load leveled by comparing bookings forecasts with shipments to reduce the end of month or end of quarter delivery compression. Customers predictably receive what they ordered, for a fair price, according to a pre-arranged schedule for shipments.

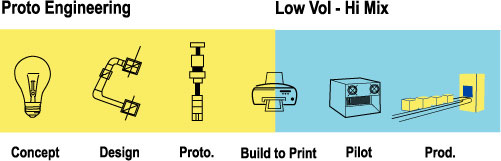

Product Realization

Most customers who engage with dataCon early in a product life cycle realize shorter times to market, ongoing life cycle materials planning plus several other total cost of ownership benefits. We would appreciate the opportunity to discuss your product requirements and needs in more detail. Please contact us.